Handling hazardous fluids places added responsibility on industrial systems. Chemical exposure, leak prevention, and equipment reliability all depend on correct pump selection. When fluids pose risks to people, processes, or the environment, safety is no longer a secondary consideration. It becomes the foundation of system design.

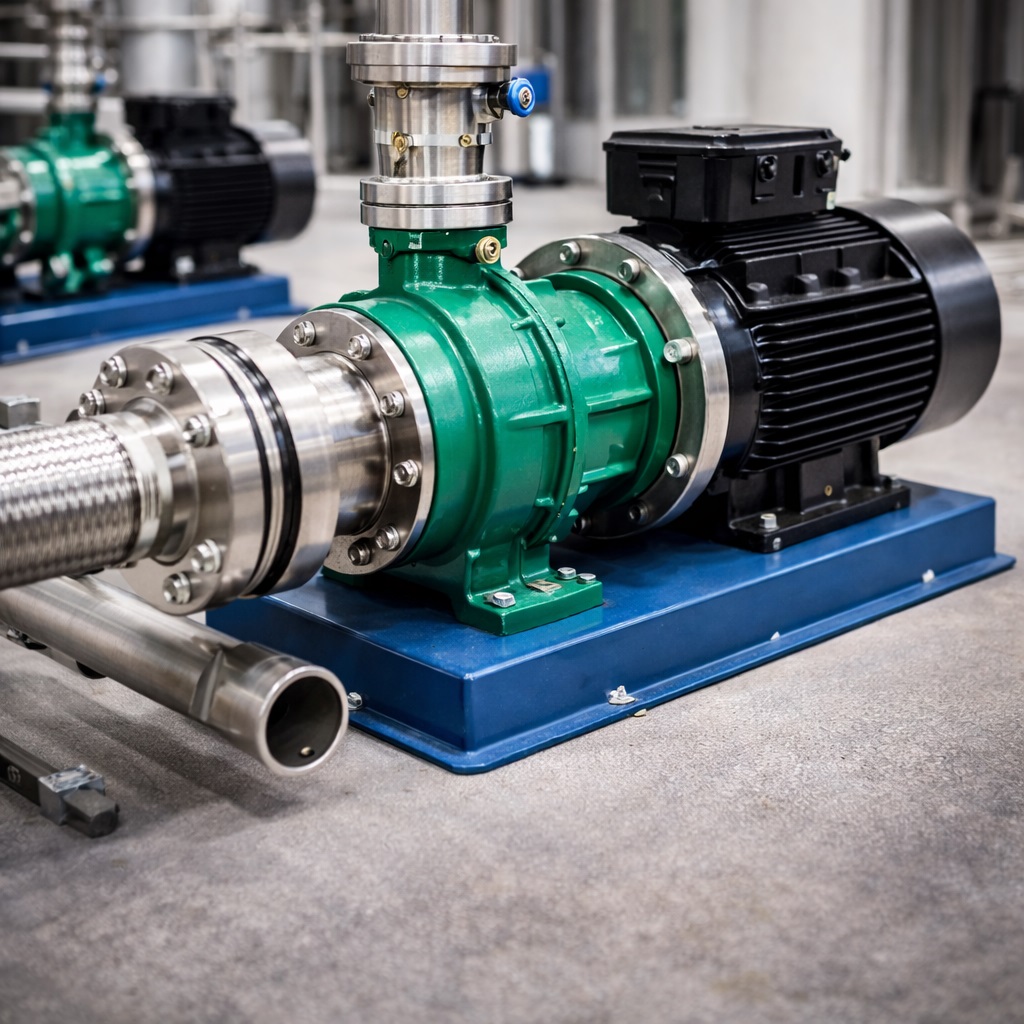

Mag-drive pumps and mechanical-seal pumps are two standard centrifugal pump designs for hazardous fluid handling. Each manages risk differently. Understanding how these designs address leakage and containment supports safer, more predictable operations.

Why Pump Selection Matters for Hazardous Fluids

Pump selection directly influences how hazardous fluids remain contained during normal operation and abnormal events. A mismatch between fluid properties and pump design increases the likelihood of leaks, seal failure, or unplanned downtime.

Key safety considerations include:

- Containment of toxic or corrosive liquids

- Reduction of fugitive emissions

- Protection of personnel and surrounding equipment

- Long-term reliability under continuous duty

When pump design aligns with fluid characteristics, risk exposure decreases across the entire system.

What Makes a Fluid “Hazardous” in Industrial Applications

A hazardous fluid presents safety concerns due to its physical or chemical properties. These fluids often require additional safeguards during transfer and circulation.

Common characteristics include:

- Corrosive behaviour that degrades metal surfaces

- Toxicity that creates exposure risks during leaks

- Volatility that increases vapour formation

- Elevated temperatures that stress seals and materials

Pump designs must account for these variables to prevent leaks at shaft penetrations and casing joints.

How Mag Drive Pumps Address Leakage Risk

Mag drive pumps use a sealless construction. Torque transfers from the motor to the impeller through a magnetic coupling rather than a direct shaft connection. This design eliminates the need for mechanical seals.

Safety advantages include:

- No dynamic shaft seal exposed to the atmosphere

- Reduced risk of external leakage

- Improved containment of hazardous chemicals

- Lower emissions in regulated environments

Because the pump casing remains fully sealed, mag drive pumps are often selected for applications requiring leak prevention. These pumps work well for transferring corrosive or toxic chemicals, where leak prevention is a priority.

How Mechanical Seal Pumps Manage Hazardous Fluids

Mechanical seal pumps rely on engineered sealing faces around the pump shaft. These seals limit fluid escape while allowing rotational movement.

Key safety features include:

- Single or double seal configurations

- Seal support systems that manage pressure and temperature

- Material options compatible with aggressive chemicals

When properly selected and maintained, mechanical seal pumps support hazardous fluid handling in diverse applications. These applications include process conditions that exceed the operating limits of sealless designs.

Where Each Pump Design Is Typically Preferred

Both pump types support hazardous fluid handling, but operating requirements influence suitability.

Magnetic drive pumps are often preferred when:

- Leakage tolerance is extremely low

- Fluids are corrosive or environmentally sensitive

- Continuous operation is required with minimal maintenance

Mechanical seal pumps are commonly used when:

- Higher pressures or temperatures are present

- Solids or crystallizing fluids must be managed

- System conditions require flexible sealing arrangements

Selection depends on balancing safety goals with operational realities.

Common Misconceptions About Hazardous Fluid Pump Safety

Several misconceptions influence the decision when choosing MTA series mag drive pumps:

- Sealless pumps are not immune to internal wear

- Mechanical seals are not inherently unsafe

- Material compatibility matters as much as the sealing method

- Proper system design remains essential regardless of pump type

Safety outcomes improve when design choices reflect real operating conditions rather than generalized assumptions.

Choosing the Right Pump for Safer Chemical Handling

Effective hazardous fluid handling relies on understanding how pump design, fluid properties, and system conditions interact. Both pump designs can support safer operation when applied under appropriate conditions.

Selection should consider:

- Fluid chemistry and temperature

- Allowable leakage thresholds

- Maintenance access and monitoring requirements

- Long-term operational stability

A well-matched pump design reduces risk while supporting reliable process performance.

Safer chemical handling begins with informed equipment selection. By understanding how mag-drive and mechanical-seal pumps handle hazardous fluids differently, industrial systems can reduce leakage risk and support safer operations.

For guidance on choosing between mechanical and mag-drive centrifugal pump solutions suited to specific hazardous fluid applications, please contact our team.