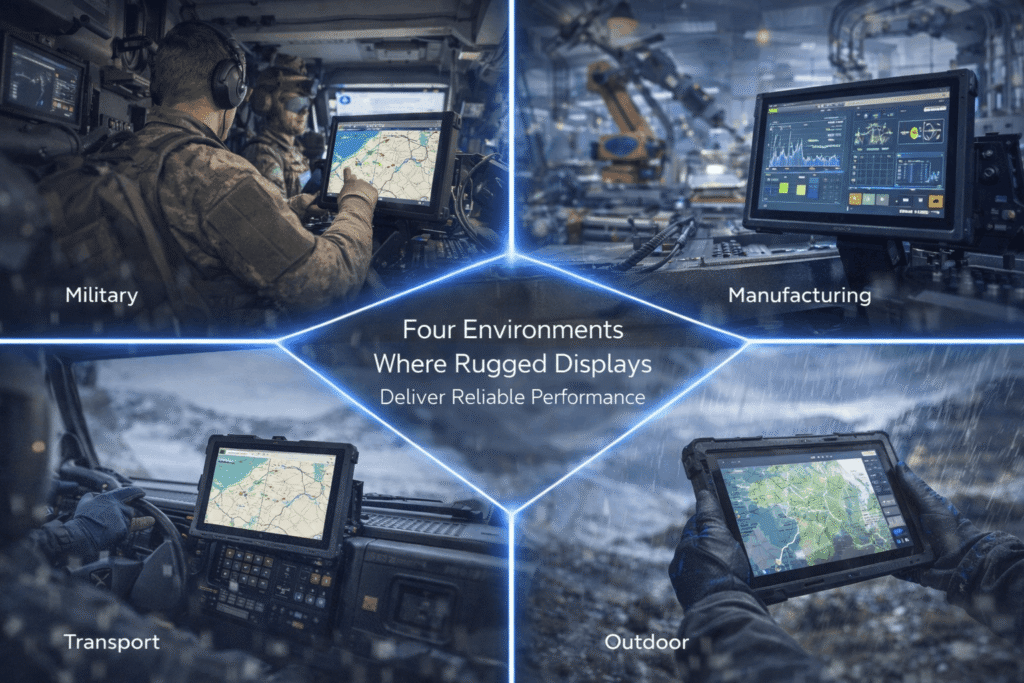

Electronic systems often operate in environments that place constant stress on display components. Temperature swings, vibration, sunlight exposure, and continuous operation all affect long-term performance. Under these conditions, standard displays often fail to maintain readability or reliability.

Rugged displays are engineered to operate reliably in settings where environmental stresses exceed standard display specifications. Understanding where rugged displays perform best helps OEMs and engineers design systems that remain dependable throughout their lifecycle.

Industrial Manufacturing and Automation Environments

Manufacturing and automation environments expose displays to mechanical vibration, airborne contaminants, and elevated temperatures. Control panels and human–machine interfaces must remain readable during extended operating cycles.

Rugged displays used in industrial automation are designed with:

- Reinforced mechanical structures

- Wide operating temperature ranges

- Stable brightness under prolonged use

- Compatibility with sealed enclosures

These characteristics support consistent performance across production lines, processing facilities, and automated systems.

Outdoor and Sunlight-Exposed Installations

Outdoor installations introduce challenges related to sunlight glare, weather exposure, and temperature variation. Displays used in kiosks, monitoring stations, or outdoor control systems must remain readable without excessive power consumption.

Rugged displays for outdoor environments typically incorporate:

- High-brightness panels for daylight visibility

- Optical treatments that reduce glare and reflections

- Materials designed to withstand humidity and temperature shifts

These features help maintain clear visual output in direct sunlight and changing environmental conditions.

Transportation and Mobile Equipment Environments

Transportation systems and mobile equipment tend to subject displays to constant motion, vibration, and mechanical shock. Whether installed in rail systems, commercial vehicles, or heavy equipment, displays must maintain consistent performance under physical stress.

Rugged display solutions designed for mobile environments address these challenges through:

- Secure mounting interfaces

- Shock- and vibration-tolerant construction

- Consistent touch responsiveness during movement

These design considerations support reliable operation in applications where equipment rarely remains stationary.

Mission-Critical and High-Reliability Environments

Mission-critical environments require displays that perform predictably under strict reliability requirements. These systems often operate continuously and must deliver accurate information without interruption.

Rugged industrial displays used in high-reliability applications prioritize:

- Long component lifespan

- Stable performance across extended duty cycles

- Predictable behavior under environmental stress

Why Environment-Specific Design Matters in Rugged Displays

Environmental stressors impact display performance in different ways. Heat affects backlight efficiency. Sunlight reduces contrast. Vibration challenges mechanical stability. Designing rugged touch displays without considering the operating environment often leads to premature degradation.

Environment-specific design allows display performance to align with real operating conditions rather than theoretical specifications. This approach reduces unexpected failures and simplifies long-term maintenance planning.

Matching Rugged Displays to Real-World Conditions

Selecting a rugged display requires evaluating how operating conditions interact with display technology. Considerations include operating temperature range, brightness requirements, mechanical stress, and expected service life. Matching display design to operating conditions helps ensure reliable performance throughout the product lifecycle.