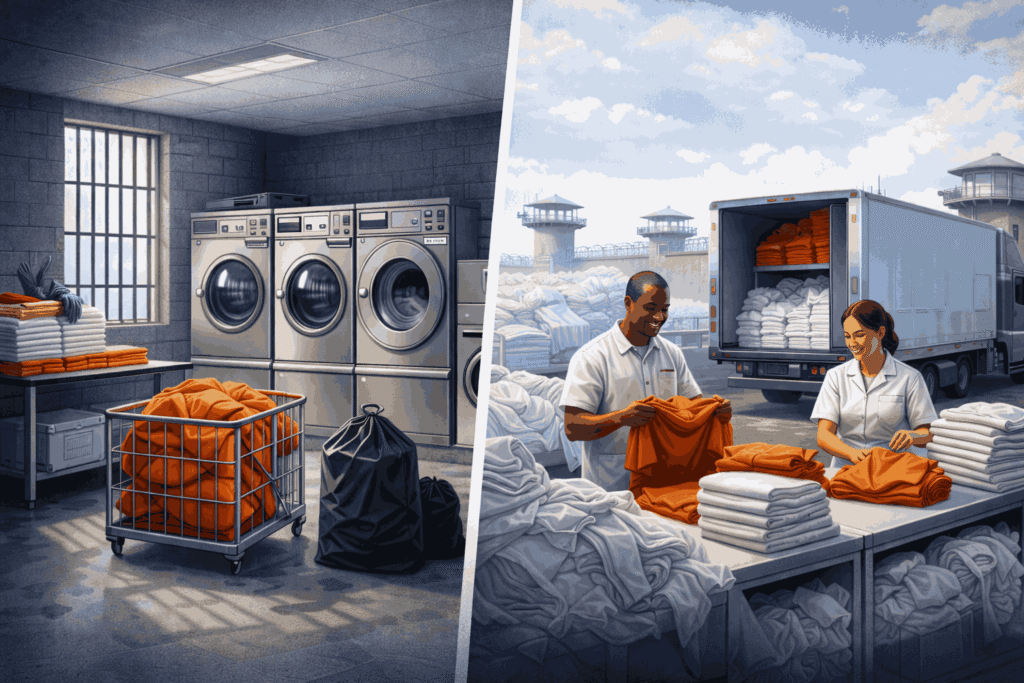

Correctional facilities process large volumes of linens daily, including bedding, uniforms, towels, and institutional textiles. These items move through rigid schedules that leave little room for error. Choosing between on-premises laundry systems and outsourced laundry services directly affects operational continuity, security, and hygiene control in prison environments.

High-capacity OPL laundry equipment is engineered to handle continuous loads, long operating hours, and heavy soil levels. In contrast, outsourced or non-industrial laundry solutions often struggle to meet the unique performance and security requirements of correctional facilities. Understanding the differences between these approaches helps facilities determine which model best supports daily operations.

Operational Demands: Prison Laundry vs Commercial Laundry Environments

Laundry operations in correctional facilities differ significantly from hotels, hospitals, or commercial laundries. Loads are repetitive, heavy, and time-sensitive. Pickup and return schedules are fixed, and security protocols restrict the movement of textiles and personnel.

Non-industrial or externally managed laundry services introduce variables such as transportation delays, inventory tracking challenges, and limited cycle control. On-premises laundry systems, by comparison, are designed to operate in secure environments, enabling continuous processing without reliance on third-party logistics.

Control and Security: On-Premise Laundry Systems vs Outsourced Processing

Security is a defining factor in prison operations. On-premise laundry equipment allows full control over textile handling, reducing risks associated with transport, loss, or unauthorized access. Linens remain within the facility boundaries, in accordance with institutional security protocols.

Outsourced laundry services require off-site handling, increasing exposure to logistical disruptions and security vulnerabilities. Delays in linen returns or inconsistencies in processing can affect housing units, medical areas, and operational schedules.

Performance and Durability: Industrial OPL Equipment vs Standard Commercial Machines

Prison laundry environments demand machines that withstand constant use without performance degradation. Durable OPL laundry equipment is built for high load capacity, reinforced mechanical structures, and long-duty cycles.

Standard commercial machines or lightly built systems are often designed for intermittent use. Under prison workloads, these systems may experience accelerated wear, frequent breakdowns, and inconsistent output. Industrial OPL equipment maintains stable performance across extended shifts, reducing unplanned downtime.

Maintenance and Downtime: Planned Servicing vs Emergency Repairs

On-premise laundry systems support proactive maintenance planning. Facilities can schedule inspections, part replacements, and servicing around operational needs to minimize disruption.

Outsourced models and less durable machines often result in reactive maintenance. Equipment failures or delayed service response times can disrupt laundry operations, forcing temporary workarounds that strain staff and resources.

Hygiene and Process Consistency: Controlled Cycles vs External Variability

Correctional facilities require strict hygiene controls due to the daily reuse of linens across housing units and staff operations. On-premise machines allow direct control over wash formulas, temperatures, and cycle durations.

Outsourced processing introduces variability in handling and wash parameters. Facilities have limited visibility into how textiles are processed, which can affect sanitation consistency and fabric lifespan.

Cost Predictability: Long-Term Equipment Investment vs Ongoing Service Dependence

On-premise laundry equipment represents a long-term infrastructure investment. While upfront costs may be higher, facilities gain predictable operating expenses, controlled energy usage, and extended equipment lifespans.

Outsourced laundry services involve recurring service fees, transportation costs, and exposure to price increases. Over time, these costs can exceed the total cost of ownership associated with durable OPL systems.

Choosing the Right Laundry Model for Correctional Facilities

Selecting between on-premise laundry equipment and alternative solutions depends on facility size, inmate population, daily textile volume, and security requirements. Key evaluation factors include:

- Load capacity and throughput consistency

- Equipment durability under continuous use

- Security alignment with facility protocols

- Maintenance access and downtime management

- Long-term operational cost control

Facilities operating under strict schedules and security constraints typically require systems engineered specifically for industrial, on-site use.

Reliability Where Operational Continuity Matters Most

Correctional facilities depend on predictable systems to maintain hygiene, security, and daily routines. On-premise laundry equipment offers control, durability, and performance consistency that outsourced or non-industrial solutions often cannot match. Strong engineering and controlled processing help support uninterrupted operations in demanding institutional environments.